Blogs & News

We have a lot of ideas and know-how about bags, material sourcing, sampling, production and a whole host of bag-related topics that we would like to share with you.

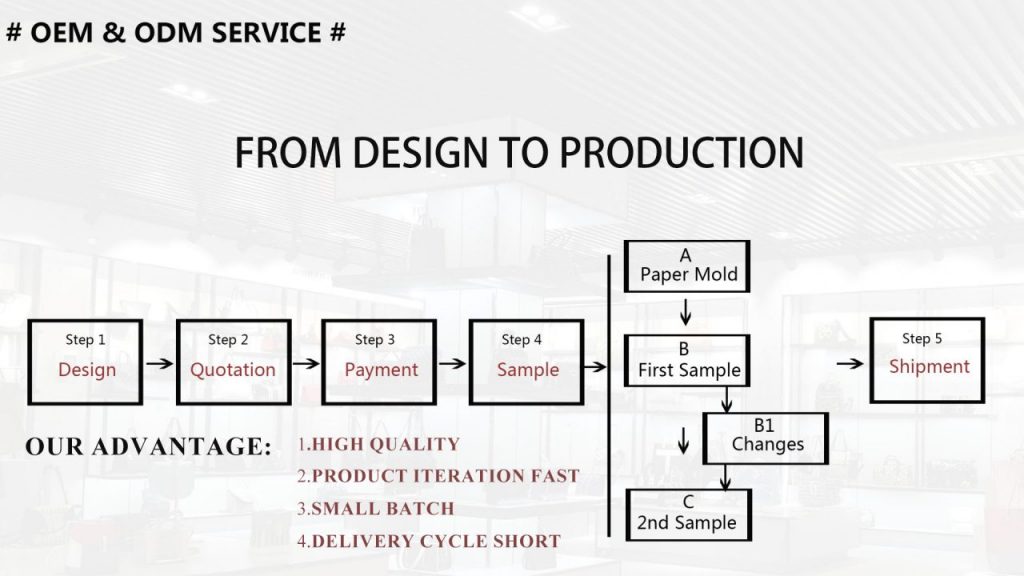

From Design to Production: How DTC Brands Can Optimize Supply Chains for Competitive Advantage

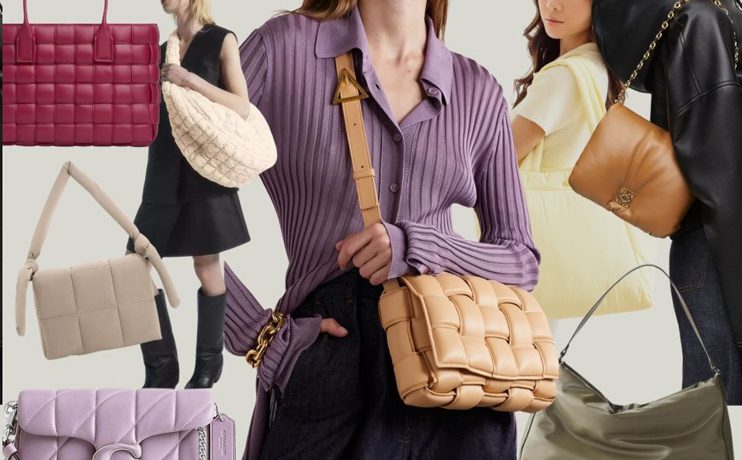

The direct-to-consumer (DTC) business model has revolutionized the way brands connect with their customers, bypassing traditional retail channels to deliver products directly to consumers. In the women’s bag industry, where style trends shift rapidly, the ability to streamline the supply chain from design to bulk production is a critical factor in achieving market success. This article explores how DTC brands can optimize their supply chains, reduce lead times, enhance efficiency, and minimize costs, thereby gaining a competitive edge.

1. The Challenges Facing DTC Brands in the Bag Market

DTC brands face unique challenges in maintaining a balance between creativity, quality, and speed.

- Short Fashion Cycles: Trends in women’s bags evolve quickly, requiring brands to move from concept to product launch in record time.

- High Customer Expectations: DTC consumers demand premium quality, customization options, and fast delivery.

- Cost Pressures: Competing with large brands requires DTC companies to keep prices competitive without compromising quality.

To navigate these challenges, DTC brands need a well-optimized supply chain that integrates design, production, and logistics seamlessly.

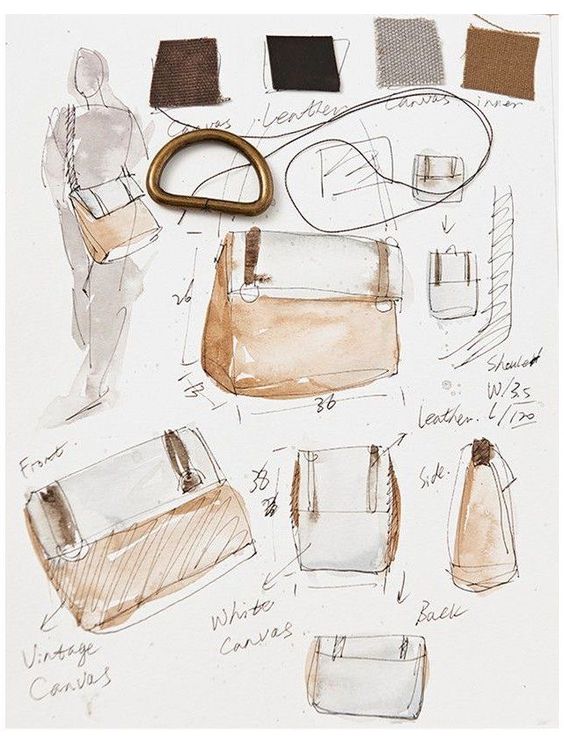

2. Streamlining the Design Process for Faster Turnarounds

The design phase is where creativity meets strategy. DTC brands must create designs that are not only aesthetically appealing but also feasible for production and aligned with market demand.

- Collaborative Design with Manufacturers: Partnering with factories that offer design consultation ensures that concepts are production-ready. Manufacturers with expertise in materials, construction techniques, and hardware can help refine designs for efficiency.

- 3D Prototyping and Digital Mockups: Utilizing digital tools to create virtual prototypes accelerates the approval process and minimizes costly design revisions.

- Trend Forecasting: Leveraging data analytics to predict consumer preferences enables brands to design products that align with upcoming trends, reducing the risk of overproduction or mismatched inventory.

3. Optimizing Production Processes for Efficiency

Efficiency in production is critical for scaling operations and meeting consumer demand. Factories with advanced capabilities play a pivotal role in achieving this.

- Flexible Manufacturing: DTC brands benefit from factories equipped to handle small-batch production or rapid scaling for high-demand products. This flexibility ensures that brands can adapt to market fluctuations.

- Automation and Technology: Incorporating automated processes, such as electric screwdrivers for hardware installation or digital cutting machines for material precision, enhances consistency and reduces production time.

- Quality Control Integration: Embedding quality checks at multiple stages of production minimizes defects and ensures that every product meets brand standards.

4. Supply Chain Transparency and Collaboration

Supply chain transparency fosters better decision-making and stronger partnerships between brands and manufacturers.

- Real-Time Updates: Using supply chain management software to track production progress in real-time helps brands anticipate and address delays.

- Communication Platforms: Regular updates between DTC brands and their manufacturing partners ensure alignment on timelines, materials, and design adjustments.

- Sustainability Practices: Transparent supply chains allow brands to implement eco-friendly practices, such as sourcing sustainable materials or reducing waste, which resonates with modern consumers.

5. Reducing Lead Times Through Integrated Operations

Shortening the time from design to delivery is a top priority for DTC brands. Manufacturers with integrated operations make this possible.

- In-House Capabilities: Factories offering a full suite of services—from design assistance to production and packaging—reduce the need for multiple intermediaries, cutting lead times significantly.

- Strategic Location: Proximity to key shipping hubs ensures faster delivery to end consumers, a crucial factor for DTC brands prioritizing speed.

6. Cost Optimization Without Sacrificing Quality

Cost efficiency is essential for maintaining profitability while offering competitive pricing.

- Material Sourcing: Partnering with factories that have access to high-quality materials at competitive prices ensures premium products without inflated costs.

- Bulk Discounts: Ordering materials in bulk for core components, such as metal clasps or standard linings, reduces per-unit costs while allowing customization in other areas.

- Lean Manufacturing Practices: Factories employing lean production techniques can eliminate waste and optimize resource utilization, directly benefiting DTC clients.

7. The Role of Customization in Strengthening DTC Supply Chains

Customization is a hallmark of many successful DTC brands. A factory’s ability to handle tailored designs without compromising efficiency is a game-changer.

- Dynamic Customization Options: Offering a range of materials, colors, and hardware choices enables brands to cater to diverse consumer preferences.

- Quick Custom Order Turnarounds: Factories with streamlined processes can fulfill custom orders faster, enhancing customer satisfaction.

Conclusion

For DTC brands in the women’s bag market, optimizing the supply chain from design to bulk production is not just an operational necessity—it is a strategic advantage. By partnering with manufacturers that offer advanced customization capabilities, efficient production processes, and transparent operations, brands can reduce lead times, control costs, and deliver high-quality products that resonate with consumers. As competition intensifies, the ability to streamline supply chains will define the future success of DTC brands in the fashion industry.

Let’s build the bags your customers will love—together.