Blogs & News

We have a lot of ideas and know-how about bags, material sourcing, sampling, production and a whole host of bag-related topics that we would like to share with you.

The Art of Customization: What Sets Our Manufacturing Process Apart

In today’s fast-paced fashion industry, customization has evolved from a niche offering into a critical strategy for brands looking to differentiate themselves and build lasting customer relationships. At the heart of this evolution lies our manufacturing process—a meticulously honed blend of innovation, craftsmanship, and technology that brings custom designs to life. In this article, we explore the unique aspects of our process and how we transform creative concepts into tailor-made products that captivate consumers.

1. A Customer-Centric Approach

Understanding and Embracing Your Vision

The journey of customization begins with a deep understanding of our client’s brand identity, target market, and vision. We believe that every successful custom product is rooted in listening closely to our customers.

Collaborative Consultation: We engage in detailed discussions and workshops with our clients to capture the essence of their brand and their specific design goals.

Market Research and Data Analysis: Leveraging data-driven insights, we identify current trends and consumer preferences that can be seamlessly integrated into your custom design.

This comprehensive understanding allows us to tailor our approach to meet your unique needs, ensuring that every product we create truly reflects your brand’s ethos.

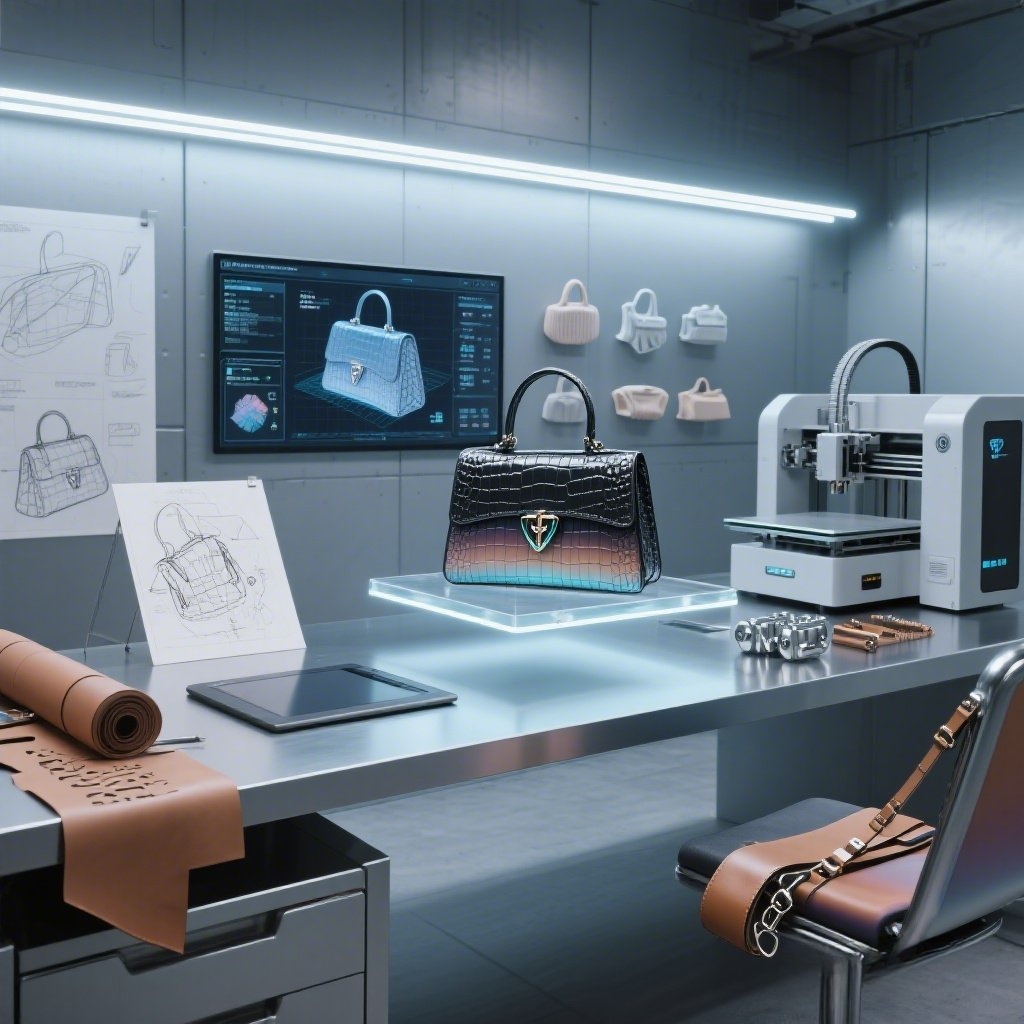

2. Cutting-Edge Design and Prototyping

Transforming Concepts into Reality

Our design process marries creativity with technology to bring your ideas to life.

Sketches to 3D Models: Our design team begins with hand-drawn sketches and then transitions to advanced 3D modeling and CAD software, providing realistic renderings that allow you to visualize every detail.

Rapid Prototyping: Utilizing 3D printing and state-of-the-art sample production techniques, we rapidly produce prototypes. This enables us to iterate quickly and fine-tune the design based on real-time feedback.

This agile prototyping phase ensures that the final design not only meets aesthetic standards but also functions seamlessly in everyday use.

3. Precision Production and Flexibility

Mastery in Manufacturing

Our production process is built on precision and flexibility, ensuring that every custom product is produced to the highest standards.

Advanced Machinery and Skilled Artisans: We combine automated technologies—such as CNC cutters and laser-guided sewing machines—with the expertise of seasoned artisans to achieve exceptional precision. This hybrid approach guarantees consistency and quality in every component.

Modular and Scalable Production: Our flexible production systems are designed to accommodate both small-batch custom orders and large-scale production runs. This scalability allows us to adapt quickly to your evolving needs without compromising quality.

This blend of technology and craftsmanship is what sets our production apart, enabling us to bring intricate custom designs to life efficiently.

4. Rigorous Quality Control

Ensuring Excellence at Every Step

Quality is non-negotiable in our manufacturing process. We implement multi-layered quality control measures to ensure that each product surpasses the highest standards.

Continuous Inspection: From raw material selection to final assembly, every stage undergoes strict quality checks. This includes detailed inspections of stitching, hardware durability, and overall craftsmanship.

Functional Testing: Beyond visual appeal, our products are rigorously tested for functionality—ensuring that zippers, straps, and compartments perform flawlessly under everyday conditions.

Transparent Reporting: We provide comprehensive quality reports to our clients, ensuring transparency and fostering trust throughout the production process.

Our commitment to quality ensures that every custom product is not only unique but also reliable and built to last.

5. Sustainability and Innovation

Pioneering a Greener Future

Sustainability is a core pillar of our customization process. We integrate eco-friendly practices throughout our operations to minimize environmental impact while delivering superior products.

Eco-Friendly Materials: We source sustainable materials such as recycled leathers, organic textiles, and biodegradable components, ensuring that our products are as kind to the environment as they are stylish.

Sustainable Production Methods: Our manufacturing process is optimized for efficiency, reducing waste through lean production techniques and energy-saving technologies.

Continuous Innovation: We invest in research and development to explore new sustainable materials and innovative production methods, ensuring that our clients stay at the forefront of both style and sustainability.

This commitment to sustainability not only enhances the value of our products but also resonates with modern consumers who prioritize ethical and eco-friendly choices.

6. Seamless Integration from Concept to Customer

The End-to-End Customization Journey

What truly sets our manufacturing process apart is our integrated, end-to-end approach that covers every stage—from initial concept to final delivery.

Holistic Process Management: Our project managers oversee the entire customization process, ensuring seamless transitions between design, production, quality control, and logistics.

Real-Time Communication: We maintain open lines of communication with our clients throughout the process, providing regular updates, progress reports, and opportunities for feedback.

Post-Delivery Support: Our relationship with clients doesn’t end at delivery. We offer robust after-sales support to address any concerns and gather insights that inform future projects.

This holistic approach guarantees a smooth, transparent experience that transforms your creative vision into a market-ready product, fostering long-term partnerships.

Conclusion

The art of customization is not merely a production process—it’s a strategic journey that transforms innovative ideas into personalized products that capture the essence of your brand. By embracing a customer-centric approach, leveraging cutting-edge design and production technologies, enforcing rigorous quality control, and committing to sustainable practices, we set our manufacturing process apart from the rest.

For DTC brands looking to make a lasting impact in the competitive world of fashion, partnering with a manufacturer that excels in customization is crucial. We are proud to offer an end-to-end solution that brings your vision to life—from concept to shelf—ensuring that every product is a testament to quality, innovation, and personalized excellence.

Let’s create something extraordinary together.