Blogs & News

We have a lot of ideas and know-how about bags, material sourcing, sampling, production and a whole host of bag-related topics that we would like to share with you.

How to Choose a Reliable Custom Handbag Supplier: A Core Competitive Advantage for DTC Brands

For Direct-to-Consumer (DTC) brands, customized products have become a cornerstone of attracting consumers and building brand loyalty. However, the customized production process involves numerous complex factors, including design, material selection, craftsmanship, lead time, and quality control. Choosing a reliable custom supplier is crucial for ensuring product quality, reducing production time, cutting costs, and improving customer satisfaction. This article delves into how to select the right custom supplier to help DTC brands gain a stronger competitive edge in the market.

1. Key Criteria for Selecting a Custom Supplier

1.1 Supplier’s Production Capabilities and Scale

Production Facilities and Technological Equipment

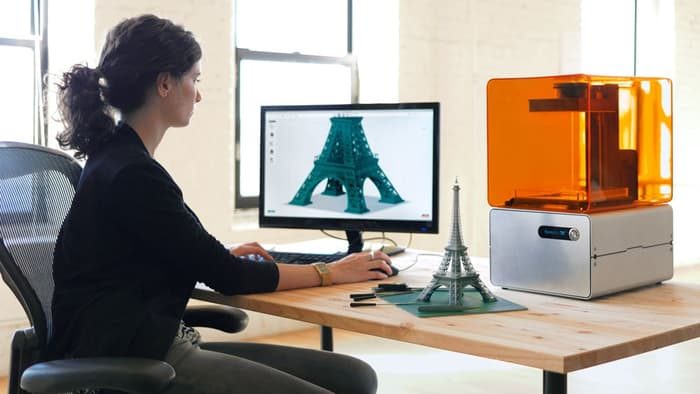

When selecting a custom supplier, the first thing to assess is their production capabilities. A supplier with advanced production facilities and technological equipment can offer higher-quality custom products while ensuring efficiency. The presence of modern equipment, such as automated production lines, digital customization technology, and 3D printing, directly affects the precision, complexity, and lead time of customized products. For DTC brands, suppliers with flexible production capabilities are especially important, as customization often requires diverse and small-batch orders.

Flexibility and Responsiveness

DTC brands often need to quickly respond to market and consumer demands, making it essential to choose a supplier that can adapt to order changes and adjust production schedules swiftly. A reliable supplier should be able to provide custom samples in a short time and rapidly adjust production and delivery schedules to accommodate demand fluctuations.

1.2 Supplier’s Quality Control System

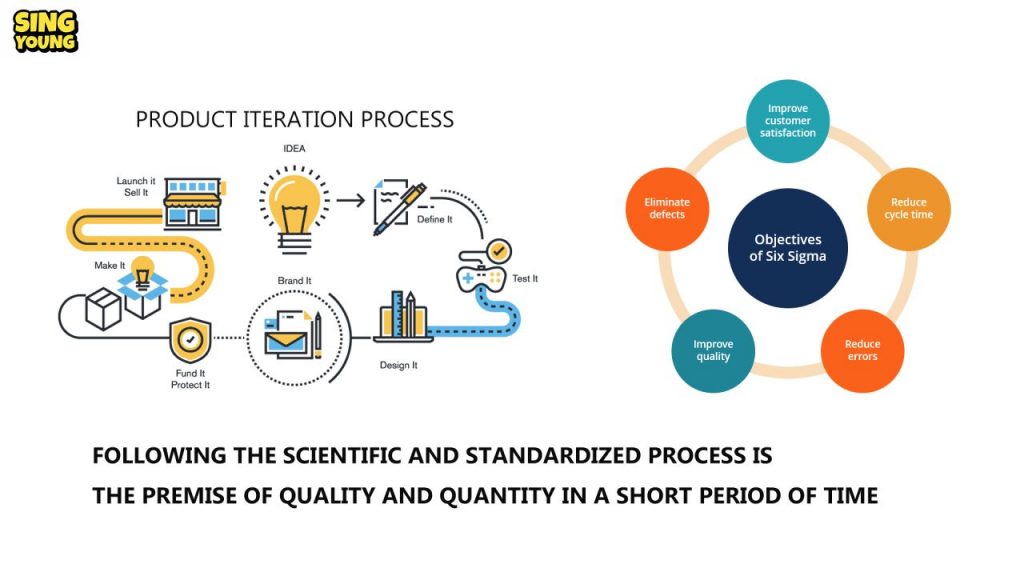

Quality Assurance Systems

Quality is the foundation of any brand’s competitiveness, and consumers have particularly high expectations for customized products. When choosing a supplier, it is essential to examine whether they have a comprehensive quality management system, such as ISO certifications or Six Sigma standards. A supplier with a robust quality control system ensures that every custom product meets brand standards and consumer expectations.

Regular Quality Inspections and Control Processes

In addition to quality certifications, the presence of regular quality inspections and control processes is an important factor in assessing reliability. A high-quality supplier typically conducts multi-stage quality checks during production to ensure each step meets standards, avoiding defects or substandard products.

1.3 Customization Capabilities and Design Support

Customization Service Capabilities

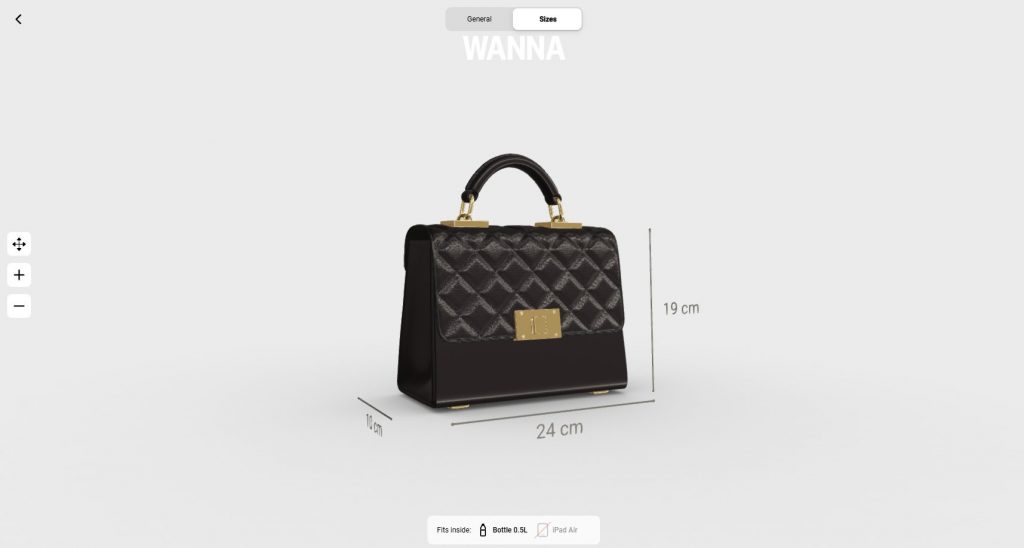

For DTC brands, customization is not just about tweaking details but involves completely personalized designs based on consumer needs and brand characteristics. The supplier’s ability to offer diverse customization options—such as color, materials, style, and size—directly impacts whether the brand’s custom products can meet consumer demands. Suppliers need to have the necessary design capabilities to provide design solutions and closely collaborate with the brand team to develop the product.

1.4 Lead Time and Logistics Management

On-Time Delivery and Production Efficiency

Customized products usually have longer lead times, and for DTC brands, quick market responses and ensuring customers receive products on time are critical. Suppliers must be able to adhere strictly to delivery timelines, as delays directly affect brand reputation and customer satisfaction. A reliable supplier should have reasonable production scheduling and an efficient production management system to ensure timely deliveries.

Flexible Logistics Support

Customized products often require tailored logistics solutions, especially in a global market where cross-border shipping and timely delivery are crucial. Suppliers should be able to provide logistics support, including warehousing, distribution, and customs clearance. A reliable supplier can not only deliver on time but also handle unexpected logistics issues, ensuring products reach customers smoothly.

1.5 Supplier’s Reputation and Credibility

Customer Feedback and Market Reputation

A supplier’s market reputation and feedback from other clients are key indicators of its reliability. Brands can review customer case studies and investigate the supplier’s industry reputation to further assess whether they meet the brand’s requirements. For large DTC brands, choosing a supplier with a strong reputation and extensive experience helps reduce uncertainties in the partnership.

Transparent Communication and After-Sales Service

A trustworthy supplier will not only provide high-quality products but also offer transparent communication and comprehensive after-sales service. Throughout the customized production process, issues like design changes, quality problems, or delivery delays may arise. Whether the supplier can promptly and effectively communicate and resolve such issues is an important factor in determining whether a brand can rely on them long-term.

2. The Supplier Selection Process and Methodology

Choosing the right custom supplier is not about making decisions based on a single criterion; it’s a systematic evaluation process. Here’s a recommended process for supplier selection:

Needs Analysis and Supplier Screening

Based on the brand’s customization needs, product characteristics, and lead times, develop clear criteria for screening suppliers. Explore potential suppliers through industry exhibitions, B2B platforms, or referrals from peers, and conduct preliminary evaluations.

Supplier Site Visits and Technical Assessment

Conduct on-site visits to potential suppliers to evaluate their production facilities, technical capabilities, quality control processes, and workforce quality. Simultaneously, conduct a technical assessment to understand their ability to support the brand’s customization needs.

Sample Production and Trial Orders

After establishing an initial partnership, assess the supplier’s actual capabilities by placing small-batch custom sample orders. Trial orders help brands better understand the supplier’s production capacity, lead times, and product quality.

Contract Signing and Long-Term Collaboration

During the evaluation process, ensure that a detailed contract is signed, clarifying production, delivery, and quality control requirements. By establishing a long-term collaboration, the brand can maintain close communication with the supplier and adapt to market changes together.

3. Conclusion

For DTC brands, choosing a reliable custom supplier is not just a supply chain management issue—it is one of the key factors that can help a brand stand out in the market. By comprehensively evaluating suppliers based on production capabilities, quality control systems, customization support, delivery times, and reputation, brands can ensure their custom products are of high quality, efficient, and meet customer satisfaction. In a competitive market, selecting the right supplier provides brands with a solid foundation, enabling them to grow and develop steadily over the long term.