Blogs & News

We have a lot of ideas and know-how about bags, material sourcing, sampling, production and a whole host of bag-related topics that we would like to share with you.

A Comprehensive Guide to Bag Manufacturing: From Concept to Delivery

Embarking on your first bag manufacturing project can be both exhilarating and daunting. Whether you’re envisioning a unique design or replicating an existing style, our expert team in Guangdong, China, is here to guide you through every step of the process. With years of experience crafting a wide variety of bags, we bring expertise and enthusiasm to your project, ensuring a seamless journey from initial sketch to final delivery. Below is a polished, step-by-step guide to the bag manufacturing process, designed to deliver high-quality results tailored to your vision.

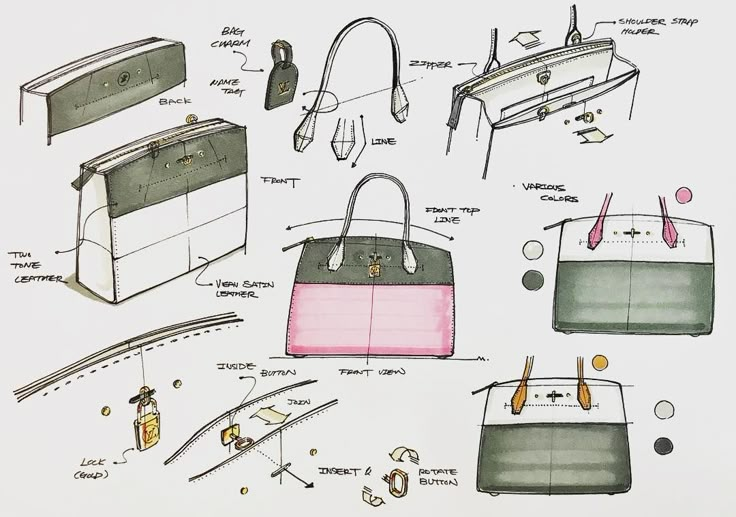

1. Conceptualization and Sketching

Laying the foundation for your bag design

Every bag begins with an idea. This stage involves creating a sketch or mood board to capture your vision, whether it’s a rough draft or a refined design from a professional designer. If you have an existing bag you’d like to adapt, our team can formalize your concept into a detailed design visual, incorporating suggestions and alternatives as needed.

Key considerations at this stage include:

- Purpose: What is the bag’s intended use? Who is the target audience?

- Design Elements: Define the bag’s size, shape, and functionality, such as the type of fastening or fabric suited to its purpose.

This foundational step ensures your idea is clear and actionable, setting the stage for the next phase.

2. Material and Component Selection

Choosing the right fabrics and hardware

With the design concept in place, we focus on selecting the materials and components that bring your bag to life. Decisions at this stage include:

- Fabric: Based on the bag’s purpose and your budget, options range from eco-friendly Fairtrade organic cotton to synthetic materials. Fabric weight impacts cost, with heavier fabrics being more expensive.

- Hardware and Closures: Choose from buckles, branded metal poppers, Pantone-matched zippers, or other fastenings to enhance functionality and aesthetics.

- Straps: Decide on the number, length, and material of straps (e.g., PU or cotton webbing, adjustable or fixed).

Once these elements are selected, we provide a detailed quote based on the required materials, order quantity, and design specifications.

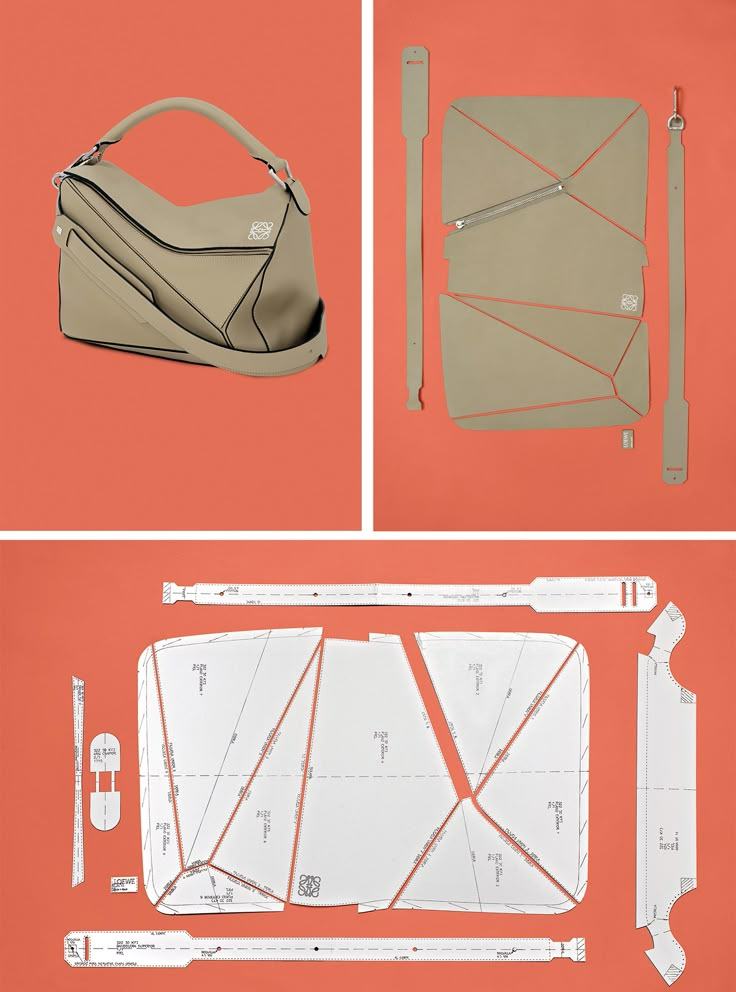

3. Paper Pattern Development

Creating the bag’s blueprint

Upon approval of the quote and receipt of a deposit, we create a paper pattern—the blueprint for your bag. This involves:

- Measuring and mapping out panels, folds, and seam allowances.

- Positioning zippers, buttons, and other hardware for precision.

- Producing a detailed representation of the bag’s final form.

The paper pattern ensures accuracy and serves as the foundation for the sampling phase.

4. Hand Sampling

Crafting a physical prototype

Before full-scale production, we create a handcrafted sample of your bag. Our expert sample makers use the paper pattern to cut fabric and assemble a pre-production prototype, incorporating all specified components and hardware.

Key aspects of this stage:

- Purpose Testing: The sample allows you to test the bag’s functionality—check if pockets accommodate intended items, evaluate strap length, or assess comfort with outerwear.

- Material Notes: The sample uses materials from small batches, which may slightly differ from bulk production due to natural variations in fabric or hardware sourcing.

- Color Matching: If Pantone-matched fabric is required, we provide dye swatches for your approval. Dyeing can take 6–8 weeks, but overprinting is available for faster turnaround, coloring only the exterior while leaving the interior white.

The sample is shipped to you for review, enabling feedback from you or your clients to ensure the design meets expectations.

5. Design Refinement

Perfecting the bag based on feedback

After evaluating the sample, minor adjustments may be made to refine the design. Examples include resizing pockets, adjusting gusset depth, or adding internal compartments for better organization. If significant changes are needed, a second sample may be required. We cover the cost of additional sampling if errors are on our end; otherwise, a fee may apply for major revisions.

6. Bulk Material Sourcing

Procuring materials for full production

Once the sample is approved, we calculate and source materials for the full order. This includes:

- Fabric: Purchased in bulk and, if required, sent to a dyeing mill for Pantone-matched coloring, then returned to our factory.

- Components: Zippers, embossed poppers, woven labels, or personalized zip pulls are manufactured to specification.

This stage ensures all materials are ready for efficient, high-quality production.

7. Pattern Cutting

Precision cutting for consistency

Using the approved paper pattern, we create templates for our cutting machines to ensure precision across all panels. Each panel includes a small margin for seams, tailored to the bag’s design (e.g., a simple tote with front and back panels or a shopper with additional gussets and side panels). A team member oversees the process to guarantee accuracy, whether producing 200 or 10,000+ units.

8. Sewing

Bringing the bag together

Sewing transforms cut panels into a cohesive bag. We employ various stitching techniques based on the design:

- Straight Stitch: Versatile for most seams.

- Zigzag Stitch: Adds flexibility and strength, ideal for stretchy fabrics.

- Overlock Stitch: Prevents fraying, perfect for seams and hems.

Our machinery, including single-needle machines, multi-needle machines, and sergers, ensures precision and consistency, with automated systems enhancing efficiency for large orders.

9. Assembly

Integrating components and hardware

Assembly involves attaching straps, handles, zippers, linings, and hardware like buckles or rivets. Specialized tools and machines ensure secure and precise attachments, maintaining the bag’s functionality and aesthetic appeal.

10. Initial Quality Control

Ensuring production accuracy

As bags come off the production line, our Quality Control Manager conducts an initial inspection, checking for:

- Correct print direction, hardware placement, and zipper orientation.

- Consistent handle length, reinforced stitching, and properly aligned pockets.

Loose threads are trimmed, and a checklist ensures every detail aligns with the approved sample.

11. Final Quality Control

Perfecting the finished product

Once all bags are assembled, a comprehensive quality control process begins. A proportion of the order is randomly inspected against the specification checklist, ensuring:

- All components (e.g., zippers, labels) meet design requirements.

- Finishes are flawless, with no loose threads or imperfect prints.

For orders exceeding 5,000 units, an external audit team conducts additional checks, with customizable inspection criteria based on your preferences.

12. Packing

Preparing for shipment

Bags are ironed, packed in compostable protective bags, and placed in cardboard shipping cartons. Packing lists detail the number of units per carton (e.g., 60 units per carton, with 15 units per compostable bag). Our eco-friendly packaging protects against moisture and odors during transit while being biodegradable for minimal environmental impact.

13. Shipping and Logistics

Delivering your order

We offer cost-effective and eco-conscious shipping options:

- Sea Freight: Ideal for orders over 500 units, taking 5–6 weeks with a lower environmental impact.

- Air Freight: Available for faster delivery when time is critical.

- Partial Shipments: For large orders, we can ship select cartons early upon request.

Why Choose Us?

From 200 units to tens of thousands, every project receives the same dedication and expertise from our Guangdong team. Whether you’re starting with a simple sketch or a detailed brief, we’re ready to bring your vision to life. Contact us today with your bag criteria, and let’s create something extraordinary together!